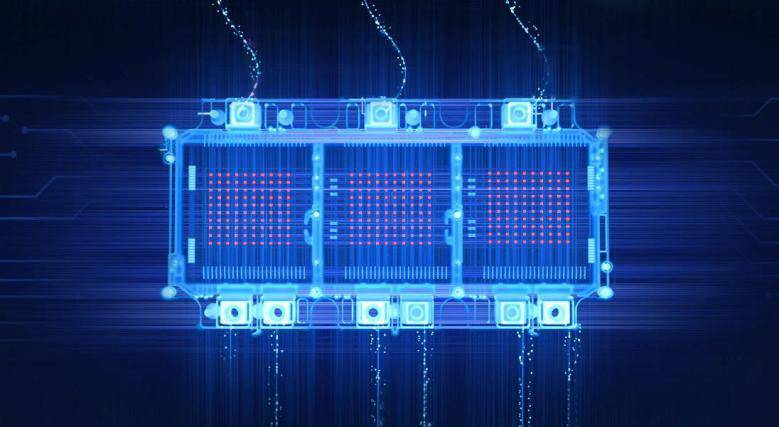

Qingdao JZ LEAPSiC Semiconductor Co.,Ltd., founded in 2021 and located in Smart Park, Jiazhan Zhigu, Qingdao, is committed to the research, development and production of the third-generation wide band gap semiconductor power devices and power modules. With cutting-edge technologies for auto-grade silicon carbide MOSFETs and diodes, and profound design and process research and development capabilities with full intellectual properties, the company has broken through the monopoly of foreign leading manufacturers on silicon carbide technology and become an outstanding enterprise in the silicon carbide power semiconductor industry in Greater China.

copyright © 2022 leapsic-semi.Com Qingdao JZ LEAPSiC Semiconductor Co., Ltd. Lu ICP B No. 2022034211